Mastering Manufacturing in the Digital Age: 10 Key Takeaways on Staying Competitive with IIOT

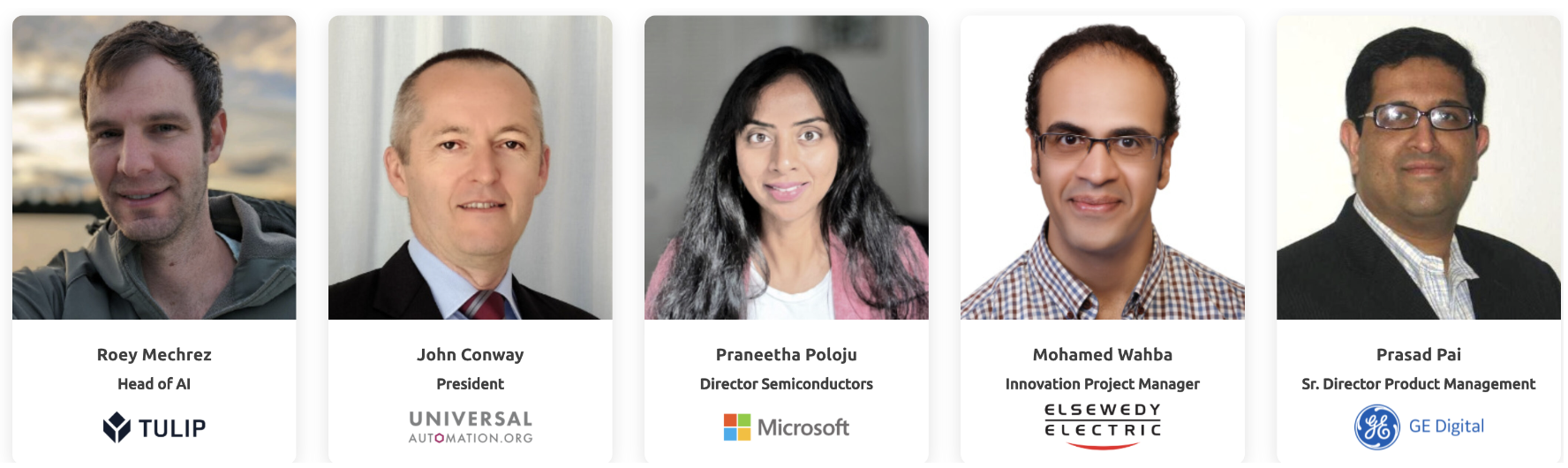

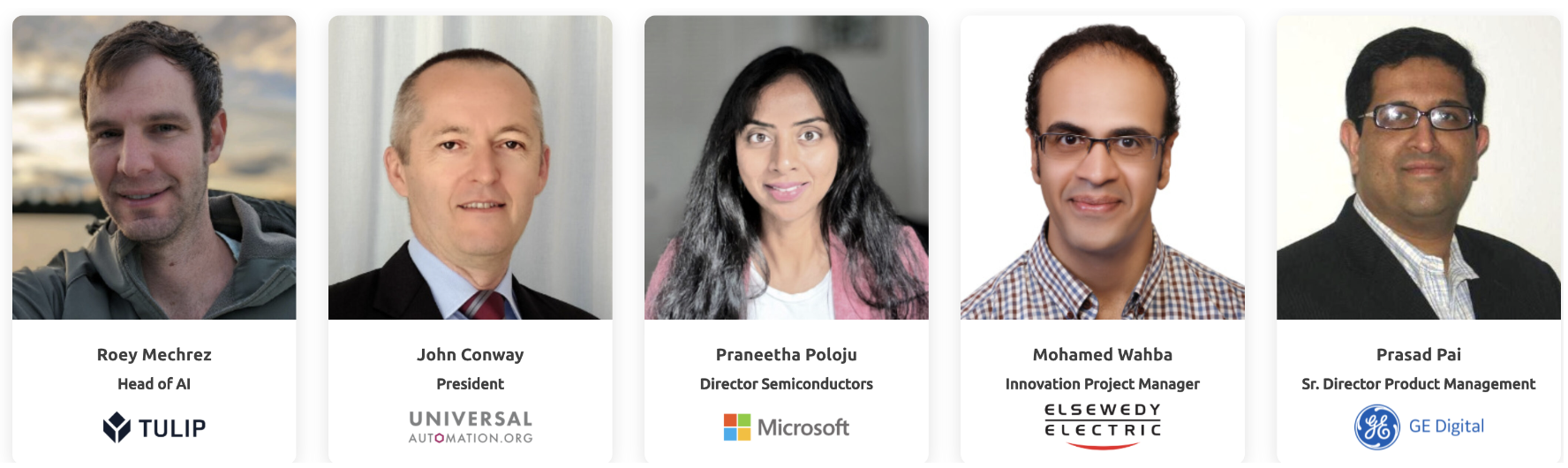

Jane Arnold and five industry experts identified ten key takeaways from a recent panel discussion, "Rethinking IIoT to Stay Competitive in the Manufacturing Industry," at the ALL THINGS IIOT DAY, presented by IIoT World.

The key takeaways all point to the importance of making flexibility and resilience top priorities!

THE IIoT PANELISTS WERE:

Highlights

- The presentation was deemed the most captivating during the All Things IIOT Day event.

- This session had an average of 1,746 registrants and 341 live attendees. View the live session by clicking here!

Key Technical Takeaways

- One of the biggest opportunities to be leveraged by IIoT is to modernize legacy systems with affordable IIoT sensors. Easily transforming these legacy systems is a crucial factor in Operational Effectiveness improvement.

- Industrial automation systems (DCS, PLC, etc.) are proprietary, which makes adding a solution, such as a digital twin, difficult to scale. It is necessary to have a shared source runtime execution engine for real-time control based on IEC-61499 to make the solutions scalable.

- Just having data is meaningless without getting insights. Utilize business processes for insights to influence production in data-to-day mode. Data to insights lead to value.

- Organizations need to first look at their data management philosophy. Do they have enough data? What is the data telling them? What data is missing? Answering these questions will help companies to plan a transformational approach to improvements utilizing data and IIoT.

- Businesses that prioritize data can gain valuable performance insights. Since processes are interconnected, data sharing is essential in complex manufacturing processes. By investing in a cloud platform, plants or factories can be transformed by making insights readily available for data-driven decisions that drive business growth.

Human-Centric Technology and Manufacturing

- When adopting technology, it's essential to consider the human-centric element. To achieve long-term success, we need to ask the right questions and use technology to augment people's abilities.

- Industrial automation struggles to attract software engineers due to proprietary code. To attract talent, manufacturing needs software that has both OT and IT components and speaks to different types of professionals, making the work more interesting.

- With technology constantly advancing, we need young people in factories to utilize it effectively. Human-centric manufacturing engages the workforce while improving efficiency.

- Industry 5.0 involves incorporating humans into the manufacturing design process. Utilizing those working at the impact point leads to improved process design.

- The concept of connected working is getting more popular. How do you make the life of every persona that operates in a factory more effective? Don’t just provide operators tools to analyze but be prescriptive with the information.

If you have any questions, please feel free to submit them directly to me at jane@momenta.one or contact any of the panelists through LinkedIn.

Momenta is the leading Digital Industry venture capital + value creation firm, accelerating entrepreneurs and leaders devoted to the digitization of energy, manufacturing, smart spaces, and supply chains. Since 2012, their team of deep industry operators has made over 120 investments in entrepreneurs and helped scale over 150 industry leaders via their award-winning executive search and strategic advisory practices.